Beyond the Leaf

In addition to our traditional leaf tobacco business, Universal continues to expand its offerings to include additional value-added services and products.

MobiLeaf ™

Real-Time Data Tracking

MobiLeaf™ tracks cultivation and harvesting data on the farm in real-time, including plot sizes, soil analyses, plant spacing, irrigation, and crop yields. This ensures accurate and up-to-date information throughout the crop’s life cycle.

Compliance Monitoring

MobiLeaf™ also assesses compliance with Agricultural Labor Practices, Good Agricultural Practices, anti-corruption laws, and local regulations. This helps ensure that all farming activities meet legal and industry standards.

On-Site Data Collection

Universal’s proprietary traceability software enables data collection directly on-site to increase accuracy and eliminate the need for re-recording data, making the process more efficient and reliable.

Blending Services

Custom Formulation for Tobacco Customers

Our Blending Services Operation (BSO) provides custom tobacco blend formulation, on-going blend maintenance, and just-in-time delivery. BSO’s proximity to the Deltafina Assisi green leaf threshing factory allows for synergies between factory personnel, production flexibility, and reduced need for destination storage. Its central European location provides access to many resources and markets.

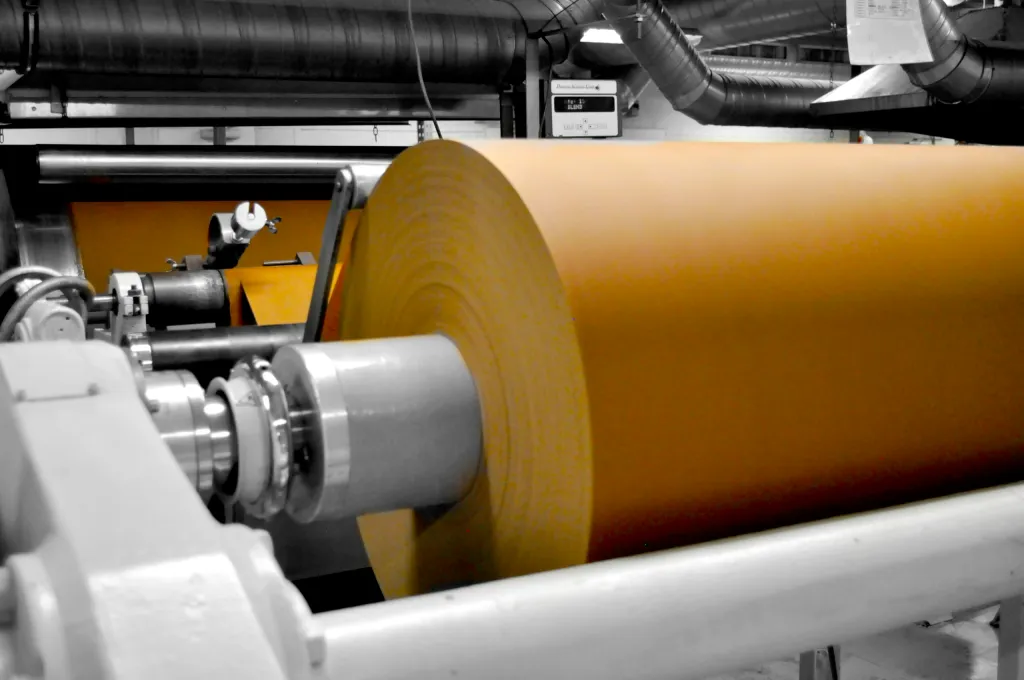

Reconstituted Tobacco

Products for Cigarette and Cigar Manufacturing

Our HTL-DHT B.V. operation in the Netherlands recycles unmarketable tobacco by-products and specializes in producing cigarette filler and cigar products, like fillers, binders, and wrappers. The company has been an expert in naturally reconstituted tobacco since the 1950s, with a focus on quality control and unparalleled market knowledge.

Modern production methods and a deep understanding of how to manipulate the factors most critical to tobacco product manufacturers – color, strength, fragrance, moisture, and, most importantly, taste – gives HTL-DHT B.V. superior product adaptability. HTL-DHT B.V. can quickly rework its products to fit new ideas, changing customer requirements, and industry trends.

Recycled Tobacco By-Products

Grade-A Compost

Carolina Recycled Ag Materials (CRAM) operates a 12,800 square-foot compost facility in Nashville, North Carolina, adjacent to Universal Leaf North America’s tobacco processing factory. CRAM composts previously unused tobacco by-products, following strict temperature requirements to ensure high-quality compost.

Our Grade-A compost has higher nutrient levels, especially potassium, compared to other composts and can be used for various agricultural and landscaping applications, including row crops, turf, and highway beautification. The initiative reduces landfill waste and provides an environmentally friendly alternative to commercial fertilizers, benefiting both the community and environment.

Next Generation Products

Liquid Nicotine

AmeriNic is a leading distiller of tobacco derived nicotine for nicotine delivery systems. We distill pure United States Pharmacopeia (USP) nicotine that is clean, tasteless, and consistent.

Proudly distilled in the United States